0086 13651986415

0086 13651986415

0086 13651986415

0086 13651986415

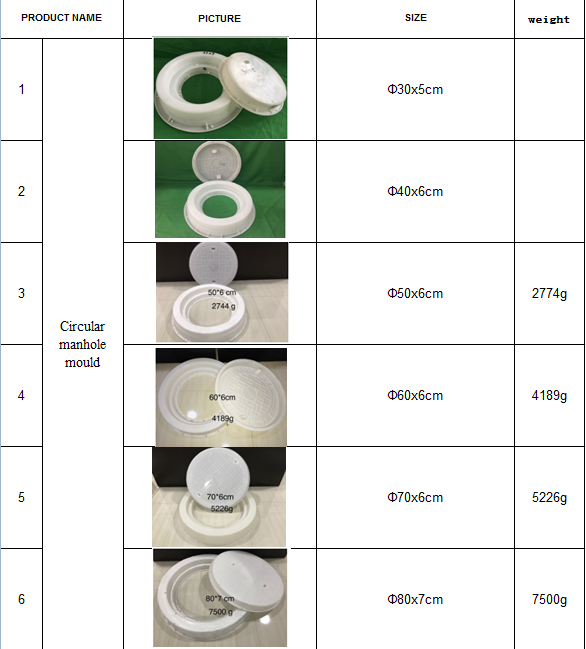

Plastic moulds

In daily life, Concrete Manhole Covers are more and more common. Manhole covers for sewers, power cables, municipal pipelines, communication pipelines, etc. Compared with cast iron manhole cover, cement manhole cover is more environmental protection, lower cost, anti-theft and other advantages.

So how to make Concrete Manhole Cover?

Using plastic mold to produce cement manhole cover is the best way. choose good quality plastic mold is very important.

The cement, sand and stone are mixed with appropriate amount of water in the proportion of 1:2:3, poured into the mold, and formed by Vibration table. In order to increase the pressure resistance and bearing capacity, steel bars, steel mesh or glass fiber can be appropriately added. 6-12 hours demoulding. After demoulding, spray water several times a day for curing. It can be used and sold in 2-3 days

The biggest advantage of concrete manhole cover is simple production, quick demoulding, smooth appearance, recyclable mould use and accurate product size. Welcome to choose our company's concrete plastic mold.